Page 52 - Kaleidoscope Academic Conference Proceedings 2020

P. 52

in STEP. For example, JSDAI can be applied for integrating planar enables motion settings of the machine parts with the

the information from both sources to create a final complete same reference. The tree structure to the left in Figure 4

STEP model containing all the information of the machine contains the kinematics information on how the different

model from the CAx tool. To ensure that the STEP file is parts and assemblies of the machine model are related to each

complete, there may be extra information such as users’ other, which determines how they move. HURCO_VM10UI

input that needs to be added. With vendor-specific is the name and model of the machine tool, and FRAME,

converters/adapters, the complete machine model in STEP Y_SLIDE and SPINDLE_HEAD are components

format can be imported into other CAx environments. The constituting the machine model. Each of the components in

vendor-specific STEP generators vary depending on the the tree structure has a breakdown structure where more

specific interface requirements and programming language information is contained for the machine model, such as the

used. The STEP generator used for the case presented in this kinematic information, which defines either the rotational or

paper will be further explained in the next section. translational movement in the x- and y-axis. Figure 5 shows

the breakdown structure for the component

4. A CASE STUDY – A STEP GENERATOR FOR SPDINLE_HEAD.

PTC CREO

We have applied the approach described in Section 3 to a

specific use case. Figure 3 shows an instance of the general

approach depicted in Figure 2. The machine tool model is

defined in PTC’s CAD software, Creo. The geometric

information of the model is exported to a STEP file. The

STEP file will be integrated with the kinematics information

generated by using J-Link and JSDAI. J-Link is a Java-based

API that is provided by PTC to enable the interactions

between the machine model in Creo and other applications.

Through J-link, kinematics information from the model can

be extracted. The geometric information in the STEP file and

the kinematics data are integrated into one STEP file by the

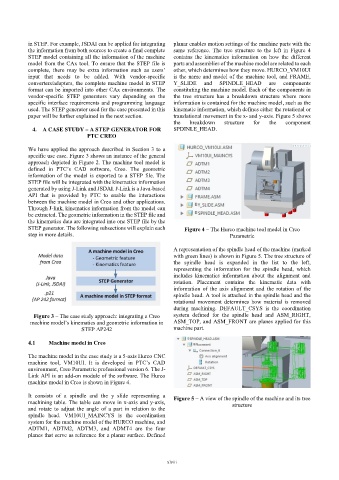

STEP generator. The following subsections will explain each Figure 4 – The Hurco machine tool model in Creo

step in more details. Parametric

A representation of the spindle head of the machine (marked

with green lines) is shown in Figure 5. The tree structure of

the spindle head is expanded in the list to the left,

representing the information for the spindle head, which

includes kinematics information about the alignment and

rotation. Placement contains the kinematic data with

information of the axis alignment and the rotation of the

spindle head. A tool is attached in the spindle head and the

rotational movement determines how material is removed

during machining. DEFAULT_CSYS is the coordination

Figure 3 – The case study approach: integrating a Creo system defined for the spindle head and ASM_RIGHT,

machine model’s kinematics and geometric information in ASM_TOP, and ASM_FRONT are planes applied for this

STEP AP242 machine part.

4.1 Machine model in Creo

The machine model in the case study is a 5-axis Hurco CNC

machine tool, VM10UI. It is developed in PTC’s CAD

environment, Creo Parametric professional version 6. The J-

Link API is an add-on module of the software. The Hurco

machine model in Creo is shown in Figure 4.

It consists of a spindle and the y slide representing a Figure 5 – A view of the spindle of the machine and its tree

machining table. The table can move in x-axis and y-axis, structure

and rotate to adjust the angle of a part in relation to the

spindle head. VM10UI_MAINCYS is the coordination

system for the machine model of the HURCO machine, and

ADTM1, ADTM2, ADTM3, and ADMT4 are the four

planes that serve as reference for a planar surface. Defined

– xlviii –