Page 135 - Kaleidoscope Academic Conference Proceedings 2020

P. 135

Industry-driven digital transformation

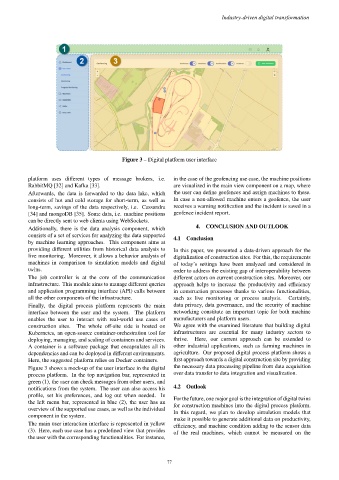

Figure 3 – Digital platform user interface

platform uses different types of message brokers, i.e. in the case of the geofencing use case, the machine positions

RabbitMQ [32] and Kafka [33]. are visualized in the main view component on a map, where

Afterwards, the data is forwarded to the data lake, which the user can define geofences and assign machines to these.

consists of hot and cold storage for short-term, as well as In case a non-allowed machine enters a geofence, the user

long-term, savings of the data respectively, i.e. Cassandra receives a warning notification and the incident is saved in a

[34] and mongoDB [35]. Some data, i.e. machine positions geofence incident report.

can be directly sent to web clients using WebSockets.

4. CONCLUSION AND OUTLOOK

Additionally, there is the data analysis component, which

consists of a set of services for analyzing the data supported

4.1 Conclusion

by machine learning approaches. This component aims at

providing different utilities from historical data analysis to In this paper, we presented a data-driven approach for the

live monitoring. Moreover, it allows a behavior analysis of digitalization of construction sites. For this, the requirements

machines in comparison to simulation models and digital of today’s settings have been analyzed and considered in

twins. order to address the existing gap of interoperability between

The job controller is at the core of the communication different actors on current construction sites. Moreover, our

infrastructure. This module aims to manage different queries approach helps to increase the productivity and efficiency

and application programming interface (API) calls between in construction processes thanks to various functionalities,

all the other components of the infrastructure. such as live monitoring or process analysis. Certainly,

Finally, the digital process platform represents the main data privacy, data governance, and the security of machine

interface between the user and the system. The platform networking constitute an important topic for both machine

enables the user to interact with real-world use cases of manufacturers and platform users.

construction sites. The whole off-site side is hosted on We agree with the examined literature that building digital

Kubernetes, an open-source container-orchestration tool for infrastructures are essential for many industry sectors to

deploying, managing, and scaling of containers and services. thrive. Here, our current approach can be extended to

A container is a software package that encapsulates all its other industrial applications, such as farming machines in

dependencies and can be deployed in different environments. agriculture. Our proposed digital process platform shows a

Here, the suggested platform relies on Docker containers. first approach towards a digital construction site by providing

Figure 3 shows a mock-up of the user interface in the digital the necessary data processing pipeline from data acquisition

over data transfer to data integration and visualization.

process platform. In the top navigation bar, represented in

green (1), the user can check messages from other users, and

4.2 Outlook

notifications from the system. The user can also access his

profile, set his preferences, and log out when needed. In

For the future, one major goal is the integrationof digital twins

the left menu bar, represented in blue (2), the user has an

for construction machines into the digital process platform.

overview of the supported use cases, as well as the individual

In this regard, we plan to develop simulation models that

component in the system.

make it possible to generate additional data on productivity,

The main user interaction interface is represented in yellow

efficiency, and machine condition adding to the sensor data

(3). Here, each use case has a predefined view that provides

of the real machines, which cannot be measured on the

the user with the corresponding functionalities. For instance,

– 77 –