Page 167 - AI for Good-Innovate for Impact

P. 167

AI for Good-Innovate for Impact

(continued)

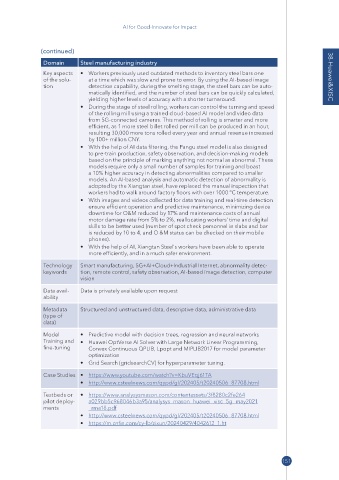

Domain Steel manufacturing industry

Key aspects • Workers previously used outdated methods to inventory steel bars one

of the solu- at a time which was slow and prone to error. By using the AI-based image 38-Huawei&XISC

tion detection capability, during the smelting stage, the steel bars can be auto-

matically identified, and the number of steel bars can be quickly calculated,

yielding higher levels of accuracy with a shorter turnaround.

• During the stage of steel rolling, workers can control the turning and speed

of the rolling mill using a trained cloud-based AI model and video data

from 5G-connected cameras. This method of rolling is smarter and more

efficient, as 1 more steel billet rolled per mill can be produced in an hour,

resulting 30,000 more tons rolled every year and annual revenue increased

by 100+ million CNY.

• With the help of AI data filtering, the Pangu steel model is also designed

to pre-train production, safety observation, and decision-making models

based on the principle of marking anything not normal as abnormal. These

models require only a small number of samples for training and boast

a 10% higher accuracy in detecting abnormalities compared to smaller

models. An AI-based analysis and automatic detection of abnormality is

adopted by the Xiangtan steel, have replaced the manual inspection that

workers had to walk around factory floors with over 1000 °C temperature.

• With images and videos collected for data training and real-time detection

ensure efficient operation and predictive maintenance, minimizing device

downtime for O&M reduced by 17% and maintenance costs of annual

motor damage rate from 5% to 2%, reallocating workers’ time and digital

skills to be better used (number of spot check personnel in slabs and bar

is reduced by 10 to 4, and O &M status can be checked on their mobile

phones).

• With the help of AI, Xiangtan Steel's workers have been able to operate

more efficiently, and in a much safer environment.

Technology Smart manufacturing, 5G+AI+Cloud+Industrial Internet, abnormality detec-

keywords tion, remote control, safety observation, AI-based image detection, computer

vision

Data avail- Data is privately available upon request

ability

Metadata Structured and unstructured data, descriptive data, administrative data

(type of

data)

Model • Predictive model with decision trees, regression and neural networks

Training and • Huawei OptVerse AI Solver with Large Network Linear Programming,

fine-tuning Convex Continuous QPLIB, Lpopt and MIPLIB2017 for model parameter

optimization

• Grid Search (gridsearchCV) for hyperparameter tuning.

Case Studies • https:// www .youtube .com/ watch ?v = KbuVEqj61TA

• http:// www .csteelnews .com/ qypd/ gl/ 202405/ t20240506 _87708 .html

Testbeds or • https:// www .analysysmason .com/ contentassets/ 3f8 280c2fe264

pilot deploy- a029bb5c96 8046b3a95/ analysys _mason _huawei _xisc _5g _may2021

ments _rma18 .pdf

• http:// www .csteelnews .com/ qypd/ gl/ 202405/ t20240506 _87708 .html

• https:// m .cnfin .com/ cy -lb/ zixun/ 20240429/ 4042612 _1 .ht

151